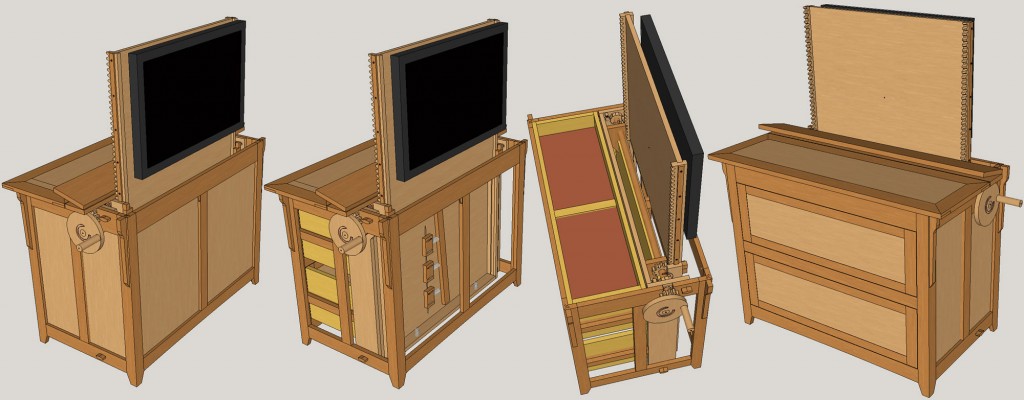

Blanket chest/TV lift

My latest project is predictably my most ambitious—a blanket chest for the foot of the bed that also holds a TV lift for up to a 32-inch TV. Right now, we have a Rubbermaid tub at the foot of the bed for comforters and blankets and our 22-inch TV is on a chest sitting at the other end of the bedroom, about 15 feet away. So this blanket chest/TV lift should solve two problems—getting the TV close enough for our middle-aged eyes to see and providing a place for blankets and pillows.

Yes, we know we shouldn’t watch TV in bed, but the problem is we like to watch BBC documentaries on YouTube and I really like to fall asleep to the sounds of Michael Wood or Simon Shama droning on about the diaspora or the Domesday Book. Our other TV is downstairs and by the time I’ve dragged myself upstairs and into bed, I’m awake again. But you don’t want a TV perched at the end of the bed all the time, so I’ve designed a TV lift that doesn’t use an expensive motorized lift. Instead, there’s a crank on the side of the chest that turns a rack and pinion, lifting the TV up. A ratchet and pawl prevents the TV from dropping back down.

And when we’re ready to go to sleep, I pull a cord that releases the pawl, allowing the TV to drop down, hopefully at a slow speed thanks to an arrester. You can see it in the second image— an inclined plane that pivots, changing the angle but slowly, thanks to three compression springs.

Of course, I’m not sure if my design will work. I’ve never cut wood gears before and I’m not sure if the gearing ratio is correct. Each turn of the crank should raise the lift 8″ and four or five cranks should be sufficient. I’m also not sure if the arrester will send the TV crashing or always leave it only partially descended. My original idea for the arresting was to put the TV lift in an airtight shaft and control the descent of the lift by air pressure, but that proved too complicated.

In addition to the novelty of making wooden gears, this design will use dovetail joints (my first attempt at dovetails; I’m going to buy a jig) for the two drawers and the removable shelf. Other challenges are the mitered legs, the half lap miters for the top and lots and lots of mortise and tenon joints. To make construction easier, the TV lift will be built outside the carcass and dropped into place. The TV lift frame will be attached to the carcass with bolts embedded into wooden handles.

I’m still working out the bugs of the design and building the many jigs that will aid in the construction. I’ve already built a new router fence, a jig to hold my belt sander at a 90° angle with a positionable rest and a crosscut sled. I still have to build a jig to hold the leg halves so that I can make the 45° lengthwise miter (to eliminate problems caused by bowed wood) and I bought a drill press. This design is too complicated to allow for freehand drilling. The tolerances are just too tight with this design.

I’ve also bought a new Starrett combination square that is outrageously expensive. Never go grocery shopping when you’re hungry and don’t go to Rockler when you’ve spent a fruitless day trying to true a cheap combination square.

I will be posting plans and videos and pictures as this project progresses, and I’ll also be looking at the various jigs I’ve made.